Using the controller 8:41

------------------------------------------------------------------------------------------------------

End Mill Types:

Square end mills are used for general milling applications including slotting, profiling and plunge cutting.

Keyway end mills are manufactured with undersized cutting diameters to produce a tight fit between the keyway slot they cut and the woodruff key or keystock.

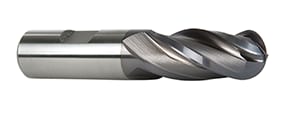

Ball end mills, also known as ball nose end mills, are used for milling contoured surfaces, slotting and pocketing. A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds.

Roughing end mills, also known as hog mills, are used to quickly remove large amounts of material during heavier operations. The tooth design allows for little to no vibration, but leaves a rougher finish.

Corner radius end mills have a rounded cutting edge and are used where a specific radius size is required. Corner chamfer end mills have an angled cutting edge and are used where a specific radius size is not required. Both types provide longer tool life than square end mills.

Roughing and finishing end mills are used in a variety of milling applications. They remove heavy material while providing a smooth finish in a single pass.

Corner rounding end mills are used for milling rounded edges. They have ground cutting tips that strengthen the end of the tool and reduce edge chipping.

Drill mills are multifunctional tools used for spotting, drilling, countersinking, chamfering and a variety of milling operations.

Tapered end mills are designed with a cutting edge that tapers at the end. They are used in several die and mold applications.

Comments

Post a Comment